The depth of the recess is set by the size of the chamfer which will be applied later once all the parts have been fitted together.īelow you can see the recess cut in the stile, which has yet to be mitered to fit with the rail.

#Stiles and rails proportions full#

The grooves are sized so that they can be run down the full length of the rails, effectively cutting the tenons to their final width.Īfter cutting the little miters on all the rails, I then recessed the stiles where they would meet the rails. Also there has been a groove cut on all the rails which will hold the kumiko grid and the bottom panel. It’s a difficult joint to describe so hopefully the pictures below will make more sense of the details. This is how the original screens were made, and how I dealt with the chamfer detail on the screens I’m building here. This method also require a recess (or mitered abutment) to be cut on the stiles. Here’s an example of the jaguchi joint on an old shoji screen that I have in the shop.Īnother method for dealing with a continuous chamfer around the rails and stiles is to miter the connection between the rails and stiles by the same dimension as the final chamfer. The name for this is the jaguchi joint, and Des King covers cutting this joint in great detail in his first book.

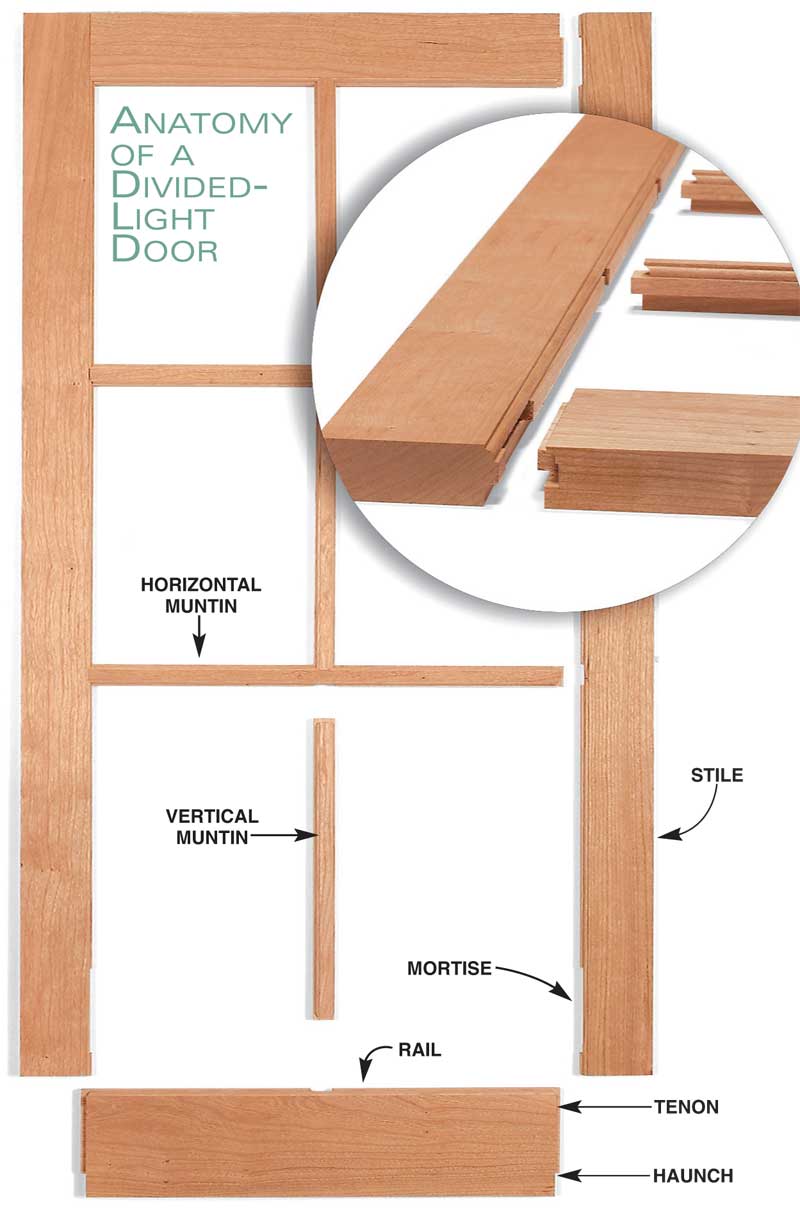

One method for dealing with the chamfer is to cut the chamfer all the way down the length of the stiles and then angle the shoulder cut on the rails to mate with the chamfer. These shojis get a chamfer all around the inside perimeter of the rails and stiles, and that detail needs to be taken into account when joining the rails and stiles. These were all cut slightly undersize with a 5/16″ hollow chisel, and then I pared the mortises to the final size of 3/8″ by hand. Here are the mortises roughed out using a benchtop mortiser. But rough cutting on the table saw and then using the horizontal router really does a great job and makes for a really accurate result.Īlso this yellow cedar machines beautifully….

I’ve never really been satisfied by cutting tenons to size straight off the table saw, there just always seems to be a bit of sloppiness in the cut, meaning the tenon is either too fat, too thin (really bad), or doesn’t have parallel sides. For the cheek cuts I oversized the cut so that the tenons would be extra thick, then I used a horizontal router (multi-router) to do the final cleanup bringing the tenons to the right thickness. After that I used a shop-made tenoning jig to cut the cheeks. My first step was to cut the shoulders for all the tenons using the table saw, then I angled the blade and cut the angle for the haunches. The haunched tenons are for the top and bottom rails and the straight tenons are for the middle rails. There are three mortises per stile, two for the top and bottom rails and one for the rail that separates the kumiko grid from the panel.Īfter laying out all the mortise I then marked and cut the tenons. The next step was to lay out all of the mortises. This is what I started with, a stack of rough milled yellow cedar.Īnd after making a lot of chips and noise I ended up with a nice clean stack of milled parts for the rails and stiles. It machines super well, it’s really satisfying to hand plane, and it smells nice too. The wood for the shojis is Alaskan yellow cedar, which is beautiful material to work with. The proportions and style were based on the existing screens. There are 20 screens that need to be made in total, and I just finished making 8 of them. The shoji screens are part of a project that my friend Yann of Mokuchi Woodworking has taken on. The past few weeks I’ve been taking a break from my folding screen project to make some shoji screens for a couple of buildings in PA.

0 kommentar(er)

0 kommentar(er)